How Amazon Uses Six Sigma and You Can Too

Typically, the companies that use Six Sigma, describe the term as a measure of quality that strives for perfection. Truth be told, There is much more to this methodology than just the perception of its key principles. If you are wondering who uses Six Sigma, read ahead for insightful information.

Each year, companies have increasingly started adopting the Six Sigma approach, which has become a keystone of the business world that welcomes rising professionals to prosperity. This philosophy gets its name from the standard guidelines to ensure the company doesn’t have any defects. Here we will discuss how Six Sigma in Amazon built its way to reach new heights.

Case Study of Amazon and Six Sigma

Today many thriving businesses across the globe have instilled some aspects of Six Sigma in their business process. However, only a few incorporate this data-driven methodology as impressively and comprehensively as Amazon. It serves as an inspiration for many companies.

History of Amazon

Jeff Bezos launched an online bookstore Amazon.com in 1994, and everyone thought it could not survive. The e-business continued to expand, selling music, pet supplies, electronics, home improvements, and pharmaceuticals. The world witnessed its evolution from a digital bookstore to a massive marketplace for third-party sellers. Amazon developed a customer base of over 30 million in the period 2000-2010.

An eCommerce giant that tops all the online retailers, a major reason is its diligent widespread application of Six Sigma principles in all the departments. Here are some unique ways in which Amazon can help you to achieve positive results.

Application of Six Sigma in Amazon

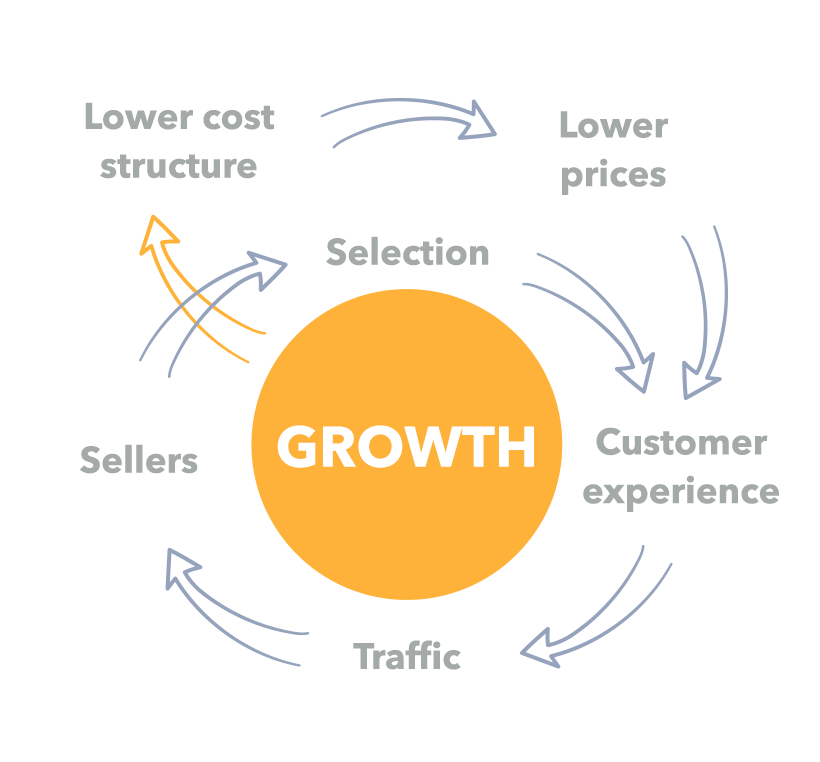

As the world witnessed, that amazon drastically expanded its product range and implemented efficient services like same-day delivery through automated drones. But can you guess how Amazon became the iconic star of electronic commerce? Yes! The answer is Lean Six Sigma Amazon.

Although the Six Sigma methodology is not clearly featured in Amazon’s public material, the Six Sigma mind frame has long been an integral part of the process. Since 1999, when the VP of operations, Jeff Wilke joined Amazon – Lean Six Sigma has been prominently factored into the business’s core operations.

“Operational excellence: To us, operational excellence implies two things: delivery continuous improvement in customer experience and driving productivity, margin, efficiency, and asset velocity across all over businesses.” -1999 Annual Report of Amazon.com

How Amazon incorporated Six Sigma into Daily Work

Six Sigma was first developed to cut costs in a manufacturing-oriented business. Hence everyone perceived that Sig Sigma might not be suitable for other kinds of businesses; however, it is not true. The Six Sigma company could belong to any sector, from healthcare and IT to retail and military. The world’s largest distributor and online retailer, Amazon, also adopted the data-driven philosophy – Thus, the words; Amazon Lean Six Sigma always go together.

Operational Excellence

Six Sigma is a core element of Amazon’s culture. Here operational excellence is defined by the continuous improvement in the customer’s experience and increased productivity, efficiency and margin across the company. Amazon receives around 4,000 orders every 1 minute, and every order is important for the company; it can’t let the standard fall.

Hiring the Right People

To achieve new milestones, Amazon adopted a common Six Sigma tactic; to hire the best and the brightest. Also, they were ahead in implementing innovative practices – they trained employees to be Six Sigma Black Belts and earn Amazon Six Sigma certification.

Six Sigma Methods

Amazon considerably reduced variations from the process by utilizing different Six Sigma tools and techniques, such as Root Cause Analysis, DMAIC, 5 WHYs, and other tools. The management could eliminate waste by reducing stages that did not add value and cultivating a Kaizen-based, continuous improvement philosophy.

Outcome

Six Sigma implementation completely transforms the company’s outcome. It comprises increased efficiency, greater inventory management, and robust value stream control.

Keep it Lean

The lean process further enhances the perspective of Six Sigma and Amazon has clearly instilled the Lead Innovation into practice to streamline its daily operations. But foremost, whatever they do at Amazon only increases customer satisfaction. Lean is all about generating value for the customers, which depicts delivering to the customers what they want to pay for. Furthermore, the logistics system needs to be efficient to deliver the package on the promised date. To understand this concept better, let’s take an example of a company that devotes more workforce to fulfill and provide excellent customer service than deploying them to the engineering side.

Similarly, continuously improving the process is another pillar of Lean, which Amazon mastered it. To ensure that there is no wasteful activity that may hamper customer experience, Amazon has introduced the Andon system, a Lean tool. It empowers the employees to ‘stop the line’, which means to stop the operational process whenever they feel it might harm the company’s value. For instance, customer service agents at Amazon can recall the products from their warehouse and off their website if they receive repeated customer complaints. In other words, all their actions focus only on improving customers’ experience even if they have to lower their margins to open more warehouses to address customers’ needs.

To achieve maximum efficiency, each job function is thoughtfully designed. It is a smart method that allows you to reduce costs and make most of the available resources. It enables you to protect your business against premature growth.

Building Business with Kaizen

Companies using Six Sigma have one ultimate goal; to grow with better results, which depicts that your company’s operational process should be on a continuous improvement path. Kaizen compliments Lean and Six Sigma, and it strongly encourages making things better along the way by engaging all the employees.

At Amazon, they have applied the Gemba walk to involve everyone in the process. Gemba refers to a value creation place. Hence, a place at Amazon where value is created is the customer service department.

So how Gemba walk works? It is quite a simple process. The supervisor or in-charge of a manufacturing factory takes a walk to the production unit and observes the progress. He audits the whole process closely, makes notes and spots areas that could improve. Discuss it with the team and involve them in developing a creative solution. Every Amazon distribution center has an assigned manager who attentively observes the workflow and ensures continuous improvement. Even if your business is not as large as Amazon’s, watching the operational process closely can highlight many areas for improvement, which could directly impact the bottom line.

Take the first step towards harnessing the full potential of change. By joining us now, you’ll unlock the tools and insights needed to drive transformation and achieve lasting success. Embrace the future with confidence and adaptability.