Kaizen vs Lean vs Six Sigma: What Are the Differences

Kaizen vs Lean vs Six Sigma

Six Sigma strives for an impressive ~99% process success rate, while Kaizen promotes continuous improvement through small, incremental changes. When comparing Kaizen vs Lean vs Six Sigma, businesses often struggle to determine which methodology best suits their needs.

Three prominent process improvement philosophies have emerged as industry standards: Lean, Six Sigma, and Kaizen. These methodologies share common goals of operational excellence and their terms are often used interchangeably. However, they differ significantly in their approach, implementation, and focus areas.

This comprehensive guide explores the origins, principles, and practical applications of each methodology, helping you determine which approach or combination of approaches best suits your organization’s needs.

Understanding the Core Principles

Kaizen

The Japanese word Kaizen (改善) combines ‘kai’ meaning change and ‘zen’ meaning good, embodying the principle of continuous improvement. At its core, Kaizen promotes daily process enhancements involving everyone from CEOs to assembly line workers. This methodology aims to eliminate waste whilst creating a more humanised workplace environment.

Kaizen’s strength lies in its participatory approach. Rather than implementing dramatic overhauls, Kaizen advocates for consistent, minor enhancements that accumulate into significant progress over time. Furthermore, since Kaizen requires minimal investment, employees feel empowered to experiment with new ideas without fear of costly failures.

Lean

Lean manufacturing, initially developed by Toyota in the 1940s, centres on five fundamental principles. First, it emphasises defining value strictly from the customer’s perspective, as typically only 10-15% of process steps add value and often represent merely 1% of the total process time. Subsequently, it focuses on mapping the value stream, creating flow, establishing pull-based systems, and pursuing perfection through continuous refinement.

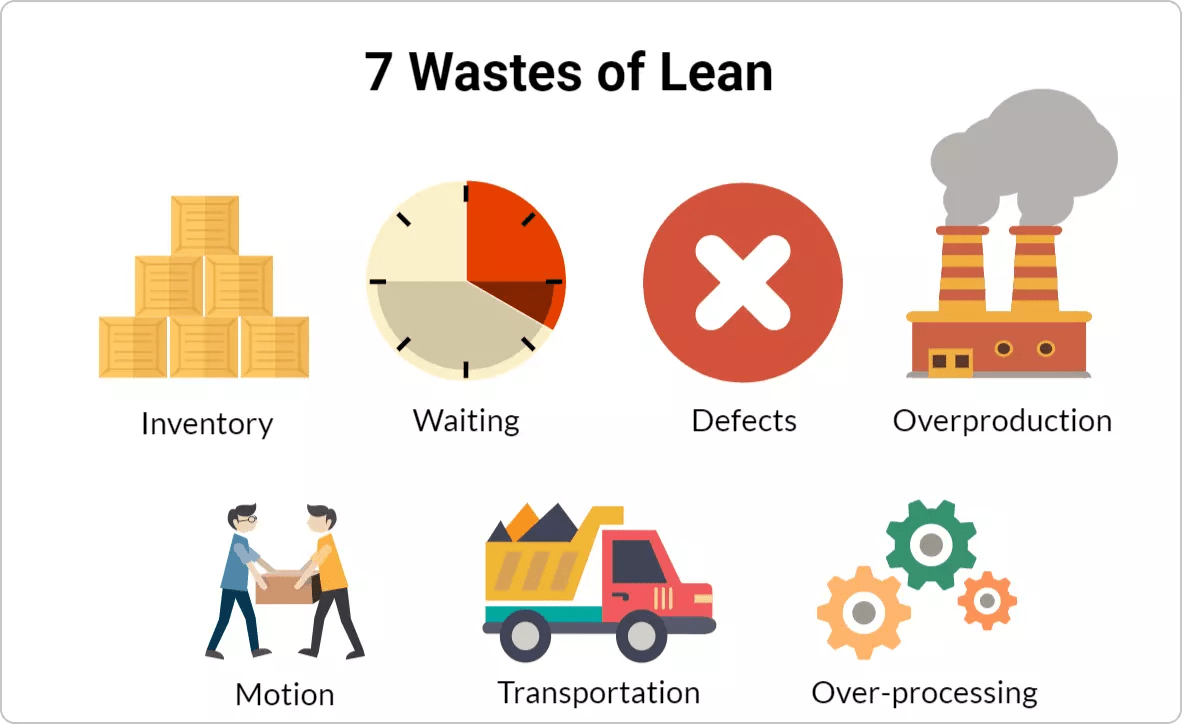

The core concept of Lean revolves around eliminating eight types of waste, known by the acronym ‘DOWNTIME’: defects, overproduction, waiting, non-utilised talent, transportation, inventory, motion, and extra-processing. Through this systematic approach, organisations can streamline their operations and enhance efficiency across all processes.

Six Sigma

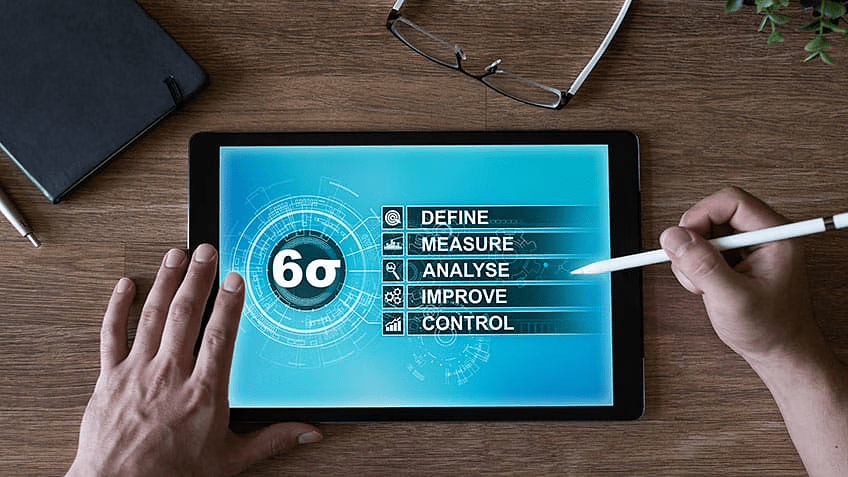

Six Sigma, developed at Motorola in 1986, aims to achieve an exceptionally low defect rate of 3.4 errors per million opportunities. This data-driven methodology employs the DMAIC framework (Define, Measure, Analyse, Improve, Control) for existing processes and DMADV for new process development. Typically, Lean Six Sigma Green Belt Certification covers these data-driven decision-making techniques, providing you with the expertise to excel in process improvement.

The methodology emphasises five key principles. Primarily, it maintains an unwavering focus on customer requirements and establishing quality standards based on market demands. Additionally, it involves thorough value chain assessment, defect elimination, stakeholder engagement, and maintaining a flexible, responsive system.

Each approach offers distinct advantages. Kaizen excels in creating sustainable cultural change through gradual improvements. Lean manufacturing proves particularly effective at reducing operational waste and enhancing process efficiency. Six Sigma’s strength lies in its rigorous statistical approach to quality control and process variation reduction.

These methodologies, although distinct, share common ground in their pursuit of operational excellence. Many organisations nowadays implement a hybrid approach, particularly Lean Six Sigma, which combines Lean’s waste elimination focus with Six Sigma’s statistical rigour. This integration allows businesses to tackle both process efficiency and quality control simultaneously, creating more robust improvement strategies.

Also read: 7 Reasons to be Lean Six Sigma Certified

9 Principles of Kaizen

Withdraw All Assumptions

Approach the business process with a fresh mindset that does not already have set perspectives on how employees are used to carrying out their tasks. This way, you can develop new ways to improve the old processes.

Solve Problems Proactively

Don’t get overwhelmed due to the magnitude of the problem; rather, look at it as an opportunity to understand and make things better. Moreover, this is a chance to display your abilities to come up with a solution.

Have Accountability

Rather than getting distracted, allocate a lot of time to what went wrong. Accept the accountability and start focusing on revising the process. Coach the team on how to move forward with improved practices.

Make Modest Improvements

It is not necessary to make big improvements, but small, and continuous improvements can go a long way. For example, find ways to make small tasks efficient, leading to more significant outcomes instead of revamping the entire department’s workflow process. Furthermore, focusing on continuous and incremental changes can result in steady growth over time.

Fix mistakes

As soon as you find the error in the process, fix it immediately. Many companies require their employees to have Kaizen certification because it teaches how to adopt a problem-solving approach and improve the process. The priority should be to focus on possible solutions and the second priority is to ensure it doesn’t re-occur in the future.

Empower the Employees

Give all team members a chance to express their opinion about how things function and what should be done to improve. This exercise makes them engaged and involved while they share their concepts and ideas. Let the people expand the pool of possible solutions.

Dive Deep into Issues

Rather than making quick fixes to the problems to meet the deadline, invest some time to dig in to find out the root cause of the issue. This method will not let you repeat the same mistakes.

Data reliance

You can always rely on data to make an effective decision. Hence, invest in collecting, analyzing, and reporting the data.

Keep going

Do not have false thinking that everything is perfect now, rather keep an eye for minor improvements that how you can make it better through Kaizen Process improvements

Join Lean Six Sigma Certification

Gain the skills to eliminate inefficiencies, make data-driven decisions, and lead high-performing teams with a globally recognized Lean Six Sigma Certification. Choose from Yellow, Green, or Black Belt and accelerate your career in leadership and operational excellence.

Take the first step—Enroll in our Lean Six Sigma course in Malaysia today!

7 Principles of Lean Six Sigma

Keep the Focus on the Customer

Every firm’s fundamental purpose is to address customers’ needs and offer them products/services they are willing to pay for. First, you need to explore what your customer wants and then analyze whether the product you offer meets their expectations. Always remember that successful firms deliver added value to the products or services defined by their client’s needs.

Even if your product is outstanding, it won’t matter if the client is not receiving any value. Enhance your ability to understand and meet customer expectations by joining our Customer Experience Training at Lean Partner today!

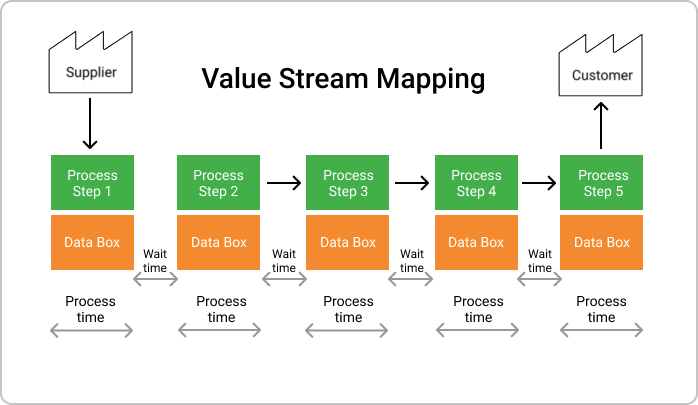

Mapping Value Streams to Understand the Work Process

Value stream mapping shows all the necessary steps in your work process to deliver value to the customer. It helps to become more efficient and effective and overall improves the workflow. It is critical to map and identify the value stream steps to establish a successful work process.

Keep Processes Flowing Smoothly

Mapping the value streams is one aspect but certainly not enough to ensure a smooth process. Various tools and techniques are used to uncover bottlenecks. For instance, once you spot where work gets stuck, you can use a suitable technique to resolve it, such as the 5 Why Analysis, to find what causes the problem and then find its solution. From here, you can identify the issues in the processes, discover the bottlenecks in the workflow, and investigate the root cause.

Remove Waste and Focus on Value

Toyota Production System (TPS) pioneered the idea of eliminating waste. Taichi Ohno, considered the father of the Toyota Production System, spent his life building efficient and productive processes. He says that TPS looks at the timeline from when the client places an order until the product is delivered. The emphasis is on decreasing the timeline by eliminating non-value-added wastes. This process can significantly optimize resources, improve operational efficiency and ultimately increase revenue.

Remove Variations to get Rid of Defects

Every successful company focuses on two elements: high customer satisfaction and cost-efficiency. Removing variation makes it possible for firms to become cost-efficient. Let’s discuss an example to understand this process. You own a Pizza cafe where every pizza-making employee puts a different amount of cheese on the dough; this leads to variation. Consequently, every customer would have different quality experiences. There is a high chance that many customers would have a bad experience, but the management can avoid this issue by standardizing the process.

Collaborate with the Team

Improving the process is an integral part of the Lean Six Sigma methodology. However, to efficiently improve the process, it is essential to collaborate with the people directly involved in it daily. Listening to their insightful feedback would immensely help to reduce waste and improve the process.

Want to improve team collaboration? Join our Lean Six Sigma Yellow Belt Certification program at Lean Partner to see how we can help!

Improve Activities in a Systematic Way

Employees often resist change in the company, and Lean Six Sigma requires many changes. Therefore, it is essential to create a systematic environment to assist employees in embracing change. With the help of data-based arguments, the company should convince the staff how significant this change is for growth.

Join Leadership Skills Training

Strong leaders drive success. Learn effective communication, decision-making, conflict resolution, and strategic leadership with our expert-led Leadership Skills Training Program. Whether you’re a team lead, manager, or executive, this program equips you to lead with confidence.

Boost your leadership potential—Join our Leadership Skills Training Program in Malaysia now!

Real-World Implementation Costs

Training costs and resource requirements play a crucial role in choosing between improvement methodologies. On average, enterprises invest in employee training yearly, spending approximately ~RM4380 per employee annually.

Training Requirements

The depth of training varies significantly across methodologies. Kaizen emphasises practical, hands-on learning where team members contribute their knowledge to improve waste management. Moreover, theoretical modules provide foundational knowledge, whilst case studies and simulations offer practical insights.

Six Sigma training follows a structured belt system, requiring approximately 8 hours of group training for certification. Nonetheless, the training intensity depends on team experience and project complexity.

Time Investment

At Lean Partner, Kaizen events typically span 3-5 days, focusing on specific problems through implementation. The complete process, including preparation and follow-up, extends to 4-6 weeks. In contrast, traditional Lean Six Sigma projects often require 8-12 weeks for completion.

Studies showed that employees engage in approximately 34 hours of training each year. The leading focus areas for training include managerial and supervisory skills (14%), mandatory and compliance training (13%), and interpersonal skills such as communication and teamwork (10%). This investment reflects the growing emphasis on continuous improvement methodologies.

Resource Allocation

Direct implementation costs encompass training, software, and project management expenses. Each methodology requires specific resource commitments:

- Kaizen demands 100% committed resources during events but offers low-risk, low-cost solutions

- Lean focuses on optimising flow throughout the value chain, requiring significant initial investment in process reorganisation

- Six Sigma needs dedicated personnel, including project sponsors, facilitators, and team members

Remarkably, employees adhering to Lean Six Sigma methodology achieved 40% higher ROI compared to those who did not. Through meticulous flow analysis and process mapping, organisations can optimise work, reduce cycle times, and boost overall productivity.

The key lies in starting small and focusing on one business area at a time. This approach ensures effective resource utilisation whilst maintaining steady progress toward organisational goals. Undoubtedly, the investment in these methodologies yields substantial returns through enhanced equipment productivity, improved service quality, and decreased material consumption.

Measuring Success Rates

Measuring success across improvement methodologies requires tracking specific metrics that align with organisational goals. Each approach employs distinct performance indicators to gauge effectiveness and drive continuous enhancement.

Key Performance Indicators

Tracking progress through Key Performance Indicators (KPIs) forms the backbone of process improvement evaluation. Lean Six Sigma KPIs primarily focus on two categories: volume metrics showing absolute values and efficiency measures displayed in percentages.

Quality-focused indicators assess product excellence, whilst productivity metrics evaluate resource utilisation against outputs. Strategic KPIs measure organisational progress, specifically tracking crucial success factors.

First Pass Yield (FPY) emerges as a vital metric, measuring the percentage of units passing inspection on their first attempt. A high FPY indicates minimal defects and reduced rework costs. Correspondingly, Defects Per Million Opportunities (DPMO) provides insights into process reliability, helping organisations benchmark against industry standards.

Industry Benchmarks

Organisations implementing Lean Six Sigma methodologies consistently achieve remarkable results. Projects executed through prescribed methods demonstrate a 90% success rate. This impressive figure underscores the methodology’s effectiveness when properly implemented.

Cycle time reduction serves as another crucial benchmark, directly impacting efficiency and customer satisfaction. By analysing cycle times, organisations identify bottlenecks and optimise workflow. Similarly, On-Time Delivery (OTD) rates reflect supply chain reliability, with higher percentages indicating superior performance.

Cost of Poor Quality (COPQ) helps quantify financial impacts of process defects. Through careful COPQ analysis, organisations can prioritise improvement initiatives effectively. Notably, Rolled Throughput Yield (RTY) measures the probability of products passing through entire processes without defects, enabling comprehensive quality assessment.

For optimal results, businesses often combine multiple methodologies. Teams equipped with both Six Sigma and Kaizen knowledge consistently deliver greater value to their organisations. This integrated approach allows companies to benefit from Six Sigma’s analytical rigour alongside Kaizen’s cultural transformation capabilities.

Join Operational Excellence Training Program

Master process improvement, waste reduction, and efficiency strategies with expert-led training. Whether you’re a manager, team lead, or executive, this program equips you with the skills to drive continuous improvement and business success.

Achieve peak performance—Join our Operational Excellence Training Program now!

Which One Should I Choose: Kaizen vs Lean vs Six Sigma

Selecting an ideal process improvement methodology depends on understanding your organisation’s unique requirements. Before implementing any approach, answering the question “What problem are we trying to solve?” proves essential for success.

Company Size Considerations

Small businesses often benefit from Kaizen’s low-cost, rapid implementation approach. This methodology excels in engaging frontline employees in problem-solving whilst promoting teamwork.

For larger enterprises, Six Sigma offers structured approaches to reduce variation and defects, making it ideal for critical processes demanding consistent quality.

Industry-Specific Factors

Manufacturing sectors typically see remarkable results with Lean methodology, as it effectively eliminates waste and optimises processes to improve efficiency. Lean proves particularly valuable when aiming to streamline operations and enhance overall productivity through identifying non-value-added activities.

Alternatively, service industries might find Kaizen more suitable, given its focus on continuous, incremental improvements. This approach helps organisations foster a culture where employees actively identify and address inefficiencies.

Current Business Challenges

For complex problems requiring root cause analysis, Six Sigma emerges as the preferred choice. This methodology shines when tackling issues that demand advanced problem-solving techniques and statistical analysis for connecting the dots. You can enrol our Lean Six Sigma Black Belt Certification program to lead strategic initiatives!

Conversely, if your organisation faces immediate challenges requiring quick solutions, Just Do It (JDI) methodology proves most effective. JDI works best for straightforward problems that need rapid resolution within 24 hours.

Remarkably, these methodologies need not exist in isolation. Many organisations achieve optimal results by combining approaches based on specific challenges. For instance, whilst Lean streamlines processes by cutting waste, Six Sigma uses data analysis to detect and eliminate problems at their source.

The key lies in fitting the methodology to the nature of the problem instead of force-fitting a problem to some predefined methodology. Through this approach, organisations can harness the unique strengths of each methodology, creating a well-rounded strategy for continuous improvement.

Conclusion

Choosing between Kaizen, Lean, and Six Sigma need not become an either-or decision. Though each methodology brings unique strengths – Kaizen’s cultural transformation, Lean’s waste elimination, and Six Sigma’s statistical rigour – many successful organisations adopt hybrid approaches tailored to their specific needs.

Small businesses might start with Kaizen’s low-cost improvements before gradually incorporating Lean principles. Larger enterprises often benefit from combining Six Sigma’s analytical tools with Lean methodology, especially when tackling complex operational challenges.

Success ultimately depends on matching the right methodology to specific organisational challenges rather than forcing predetermined solutions. Companies that carefully evaluate their size, industry requirements, and current challenges typically achieve better results than those blindly following any single approach.

Rather than viewing these methodologies as competing frameworks, consider them complementary tools within your improvement arsenal. This flexible mindset allows organisations to draw from each method’s strengths while building comprehensive, sustainable solutions for long-term success.

Transform Your Business Efficiency with Leading Operations Management Consultants. Join our Lean Six Sigma training program and Operational Excellence training program for Kaizen today!